The Facade Solution Specialists

AUSTRALIAN-OWNED SPECIALISTS IN CLADDING AND RE-CLADDING

Sought after for remediating facades on high and lowrise buildings throughout Australia, with many projects completed to date.

Product Types

- Prefinished Solid Aluminium Panel

- Powder-Coated Solid Aluminium Panel

- AS1530.1-Tested Aluminium Composite Panel

- Nu-Wall® (Australia/New Zealand Product)

- AS 5113-Tested Kasset Curtain Walling System

- Glass (Window Walls and Curtain Walling)

- Steel (Car Park Façade and Screenings)

- Perforated Aluminium Screens & Car Park Façade

- Specialty-Designed Architectural Louvres & Awnings

- Metal & Aluminium Street Art & Sculptures

Few cladding builders have amassed the same level of industry knowledge and decades-long experience as Cladding Systems.

As a specialised building contractor with over 45 years’ experience in the building and construction industry and 15 years in the façade and cladding sector, we are one of Australia’s most reputable cladding and facade contractors because we consistently deliver projects in a timely, cost efficient and professional manner.

With clients that include Lend Lease, Multiplex, Mirvac, John Holland, and Probuild, tier-1 builders appreciate our expertise, integrity, and commitment to high standards of performance.

Cladding Systems has been a leading industry builder throughout the cladding boom and has remained a reliable and competent builder throughout the cladding crisis.

Our highly qualified staff, diversified factory capabilities and experienced director allows the company to complete high-quality work on all types of projects, from apartment complexes and hospitals, to education campus and private residential developments.

With a staff of engineers, CNC programmers, architects and carpenters, as well as a director with 40 years’ experience in the construction industry, there are very few questions Cladding Systems cannot provide answers and solutions to.

We are uncompromising in the way we deliver our products and services, and have been subsequently rewarded with the loyalty of builders who value precision and timeliness from their partners.

Combustible Cladding

From the early 1990s, aluminium quickly became a popular façade solution for creative architects and builders due to its wide range of colours, formability and strength. Particularly, aluminium composite panel (‘ACP’) was an attractive external façade solution because of its thermal resistance, acoustic measurements and relatively convenient mechanical properties.

Other attractions included the fact that ACP cladding in cassette only protrudes 30mm off the face of the structural wall and is much lighter and easier to cut than solid aluminium. But ACP has come under immense scrutiny due to its fire behaviour, particularly in high-rise residential developments such as the Glenfell Tower and Lacrosse Tower; two notable instances in recent years.

For a long time, the United States and Germany have used the product with extreme caution, given how flammable the polyethylene core (‘PE’) was and the danger it posed. Contrast this with the UAE, France, the UK and Australia, where cladding with combustible PE cores was unregulated and untested for much longer than fire-engineers and suppliers should have allowed. As a result, many buildings in these countries pose a fire threat to its occupants and those nearby.

Cladding Systems has been a proactive participate in multiple Australian Standard tests that include 1530.1, 1530.3 and 5113 full scale tests. We have also commissioned and tested full-scale façade elements at Ian Benny and Associates’ facility in Dandenong, Victoria; for structural and silhouette/waterproofing compliance.

We are proud to partner with BG&E and Inhabit Engineers to always deliver a cost-effective and more importantly, compliant façade design and solution.

Test

What has the Government done?

.

Cladding Safety Victoria

A Victorian Government program allocated $600m to reduce the risk associated with combustible cladding on residential apartment buildings.

Victorian State-wide Audit

On behalf of the Victorian Government, the Victorian Building Authority (‘VBA’) has carried out over 2,200 building inspections to determine whether an ACP cladded building possesses a fire risk to its residents/tenants.

For more information, please visit:

https://www.planning.vic.gov.au/building-policy/cladding-rectification-program

Advice for concerned building owners

.

If your Building has been referred to the CSV Program by the VBA’s Statewide Cladding Audit or your Council’s Municipal Building Surveyor, speak with Cladding Safety Victoria. Please visit their website for further information.

https://www.vic.gov.au/cladding-safety

In the event your building has not been referred, please speak with your local council or the VBA.

https://www.vba.vic.gov.au/cladding

Advice for concerned tenants

- Speak to your landlord or body corporate.

- Install smoke alarms.

- Fix/unlock emergency exits, keep hallways clear to avoid obstructing occupants needing to exit the building, and keep fire stairwells and landings clear.

- Remove ignition sources (i.e. extinguish cigarettes safely).

- Do not cover air-conditioning units with clothes or other materials.

- Keep balconies clear of clutter and material such as clothing, boxes or rubbish.

- Ensure barbecues and heaters are not used near potentially combustible material.

Why choose us?

Solid Aluminium Panels

Non-Combustible Aluminium Composite Panels

Nuwall® Interlocking Cladding System

Glass Curtain & Window Wall

Secondary Steel & Screening

Pierce Stud Light Weight Framing

Metecno KASSET Walling System

Solid Aluminium Panels

Non-Combustible Aluminium Composite Panels

Nuwall® Interlocking Cladding System

Glass Curtain & Window Wall

Secondary Steel and Screening

Pierce Stud Light Weight Framing

Metecno KASSET Walling System

WE ONLY INSTALL FIRE COMPLIANT CLADDING MATERIALS.

Our team of highly-qualified architects, engineers and CNC programmers bring formidable levels of in-house expertise to each new project.

Likewise, our 40-plus years in the industry affords us access to valuable external contacts. Together, there’s no project too complex for us; we specialise in the impossible.

Test

Licenses, Qualifications, Mgmt. Systems

- Victoria Construction Supplier Register (Works)

- Victoria Cladding Rectification Register

- Victoria Unlimited Domestic Builder

- Victoria Limited Commercial Builder (Fit Out – Structural)

- South Australia Commercial Builder

- Western Australia Commercial Builder

- WHSMS Management System

- ITP and QA Management Systems

- Ability to Implement a Traffic Management Plan

- EBA – Cladding Systems Pty Ltd and the CFMEU Enterprise Agreement 2020-23

Insurances and Warranty

- Professional Indemnity Insurance (Policy Value of $5,000,000)

- Public & Product Liability Insurance (Policy Value of $20,000,000)

- Employee Workcover

- 15-year warranty on workmanship by Cladding Systems

- 15-year warranty on installed materials from suppliers (back-to-back warranty)

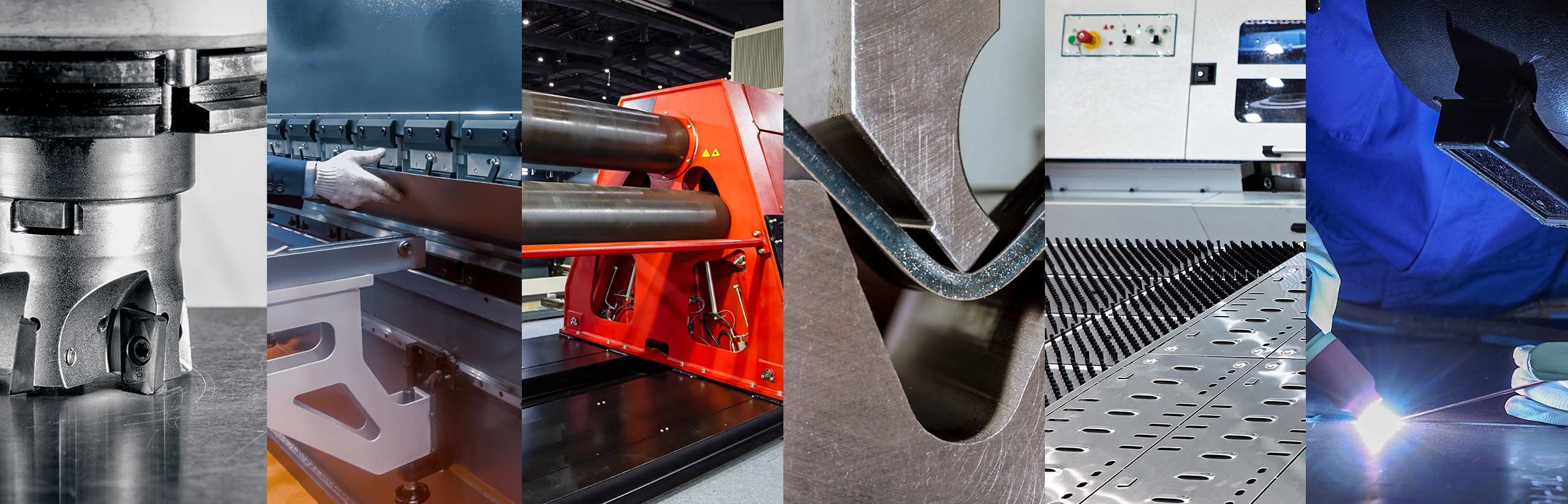

Manufacturing & Installing Capabilities

- 4 x CNC MULTICAM Routers

(2 x 3.60m, 1 x 4.00m, and 1 x 7.00m) - FormIndustrie Dali 40 (4 Axis CNC Router)

- 3 x Kemppi MasterTig AC/DC 2500

- 2 x Kemppi KempoMig Feed 4000

- 3 x Kempii WeldForce KWF 3000

- Graco Glazing [Caulking] Machine

- 2 x CNC Steelmaster Hydraulic Folder

- MetalMaster Guillotine

- Lemas Coil Roller

- Henrob Pierce Stud Riveter

- Galvanised Steel and Aluminium Scaffold

- Traffic Management and Exclusion Zone Equipment

- Trucks, Scissor Lifts, Boom lifts, Forklifts

NCC Compliant Cladding Materials

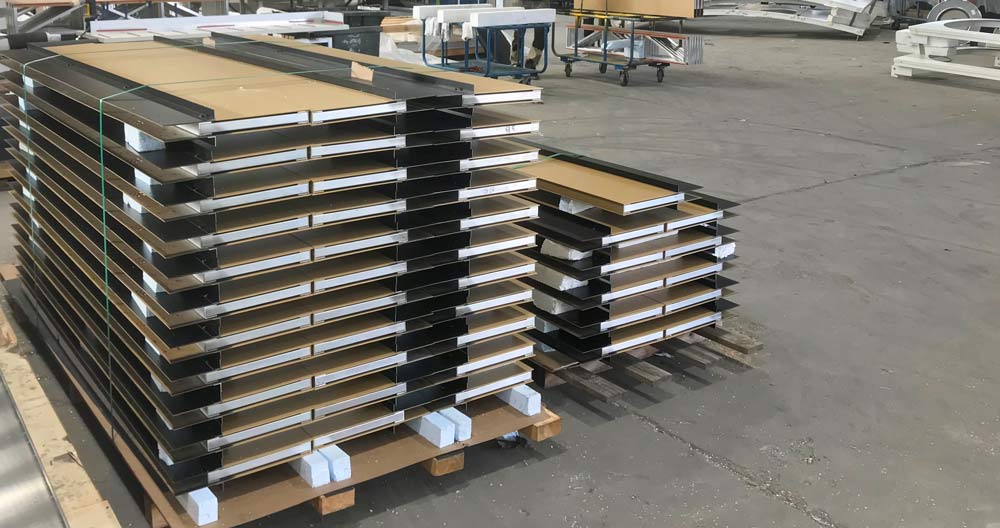

Today’s modern aluminium panels possess key qualities that separate them from the aluminium composite panels embroiled in the current crisis.

The façade materials used by Cladding Systems are constructed from solid aluminium with a thickness of 3mm up to 5 mm and no core material. As a result, they deliver outstanding fire resistance, excellent machinability, high tensile strength and impressive hail resistance.

Both products used by Cladding Systems – Alfrex and Mondoclad – are deemed non-combustible, and are available in a range of durable, high-quality finishes and colours.

Product of PRC | hvgfacades.com.au

Categorically non-combustible certified to AS1530.1, our MondoClad solid aluminium cladding panels come in a wide range of finishes and sizes to ensure even the most complex designs can be achieved.

Developed from marine grade aluminium, MondoClad is the premium solid aluminium panel solution. Offering exceptional quality and fire performance, MondoClad provides a definitive, non-combustible cladding solution with compliance and safety in mind.

Utilising a highly corrosive resistant marine grade alloy, MondoClad is ideal for installation in the harsh Australian environment. Together with its non-combustibility, low maintenance and an ability to be folded into cassettes, MondoClad makes it a perfect aluminium panel solution for new builds or recladding projects.

The superior PVDF architectural paint finish of MondoClad aluminium cladding system ensures UV stability, colour retention and a product that will stand the test of time. MondoClad delivers high-level sustainability and is 100% recyclable.

MondoClad provides architects, designers, developers, builders, and contractors a premium solid aluminium façade panel, that is non-combustible and can be safely specified for commercial, educational, aged care and residential projects without compromising design.

Close all

Key Highlights

- Non-combustible to AS1530.1

- Compliant to FP1.4 for weatherproofing – AS4284 certified

- CodeMark Certified

- 20 Year Warranty

- The ideal choice for recladding projects

- Custom sizes, colours and finishes

- Coil coated

- PVDF finish

- High quality marine grade aluminium

- Competitively priced

- A team of sales and technical experts with strong industry knowledge

- A sustainable cladding choice

- Warehousing nationally, stocked locally

Specs | Testing | Reports

Colours

Product of South Korea | alfrex.com.au

Fully rated as non-combustible and tested to Australian Standard AS 1530.1, Alfrex Solid is constructed from 100% aluminium, rather than combustible polyethelyne and fire retardant mineral like typical aluminium composite materials (ACM).

Alfrex Solid uses a range of finishes from PVDF, Kynar 500, Hylar 5000 and Duranar PPG, manufacturing by high-quality roll coating (roll-to-roll continuous) coating method.

It features both a pre-finished panel surface as well as a primer-treated reverse side for extra protection.

Unlike traditional powder-coated panels, pre-finished Alfrex Solid can be fabricated immediately, saving end-user costs, reducing damage and lead times.

Close all

Key Highlights

Origin: Manufactured in South Korea

Weatherproofing: Complies with FP1.4

Paint Finishes: 2 Coat/2Bake & 3 Coat/3Bake paint system (consisting of corrosion inhibitive primer and a fluoropolymer topcoat)

Paint Finishes: Pre-Coated with fluoropolymer paint from PPG USA for higher flexibility to machine & fold (2T/2H). PPG Duranar coatings are highly resistant to chalking, fading, chipping and peeling

Grade of Aluminium: Superior 3003 series H14 aluminium coil (easier to machine and fold than 5000 series products and can be folded to 180° without crazing)

Minimising Oxidisation: Rear surface coating to minimise oxidisation

Protective Film: High quality protective film protects the panels during installation

Warranty: 15 year manufacture warranty directly from ALFREX on the paint finish. Extended warranty up to 25 years available on request based on the project information.

Panel Sizes: Available in standard widths of 1250mm & 1575mm

Specs | Testing | Reports

Documents / Colours

Vitradual 3mm solid aluminium cassette cladding system, are NCC compliant, non-combustible to AS 1530.1, weather-proof, and highly durable, ensuring they’ll stand the test of time.

As Australia’s first solid aluminium panel, Vitradual has been the chosen cladding product for thousands of new build and rectification projects across Australia. Vitradual has been built with performance in mind.

Vitradual panels are pre-finished with high quality PVDF Kynar 500 paints, tried and tested for proven vitality and durability. The premium coatings provide the ultimate resistance to weather and industrial pollution on commercial, industrial, infrastructure and residential developments.

Vitradual panels come in an unlimited range of colours, finishes and sizes, to ensure that no design is off limits.

Fairview’s rigorous approach to quality control and assurance from design, sourcing and material testing, to regulatory compliance and product warranty, means that Vitradual is the leading choice for solid aluminium cladding solutions.

Close all

Key Highlights

- STRINGENTLY TESTED

- EXCEPTIONAL PERFORMANCE

- NON-COMBUSTIBLE

- AUSTRALIAN-FIRST

- ROBUST DURABILITY

- UNLIMITED COLOUR RANGE

- ADVANCED COATING TECHNOLOGY

- MINIMUM 15 YEARS MANUFACTURER WARRANTY

- FULL MACHINABILITY

- QUICK INSTALLATION

Specs | Brochure | Colours

Colours

Product of Japan | alpolic.com

ALPOLIC NC/A1 is a mineral core barrier, aluminium composite cladding panel manufactured by global market leaders Mitsubishi Chemical Infratec, and was developed for the Australian market.

It is fully compliant to Australian standards and suitable for use wherever a non-combustible material is required and is one of the most stringently tested products on the Australian market. It has also achieved a Euroclass “A1” rating, the first of its kind in the world.

ALPOLIC NC is a pre-finished panel utilising lumiflon FEVE paint technology to provide a paint system that requires no cleaning schedule in order to maintain the warranty and won’t degrade under UV exposure and comes in a wide range of colours.

Close all

Key Highlights

- Deemed to satisfy C1.9 (e) (vii) of the NCC2019 and is suitable for use wherever a non-combustible material is required

- Codemark certified

- Comes with an EPD (Environmental Product Declaration) produced by GECA (Good Environmental Choice Australia) and can contribute to Greenstar points

- Proven coating durability in the Australian market for over 30 years

- Manufactured in Japan by globally respected Mitsubishi Chemical

- Each panel comes with a 3 coat FEVE lumiflon paint system and comes in solid, metallic, timber pattern, sparkling and prismatic colours

- 20-year full cover manufacturer’s warranty (including rectification) and requires no cleaning schedule in order to maintain the warranty

- Guaranteed Flatness. No oil-canning

- ZERO Polyethylene in panel

- Successfully tested to AS5113

- Stocked and distributed in Australia by Network Architectural

Specs | Testing | Reports

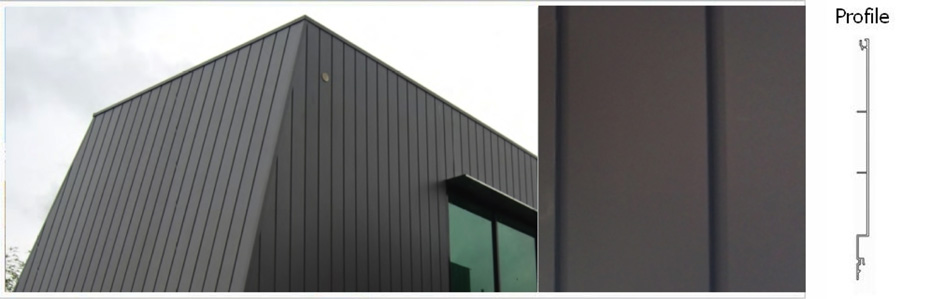

Nu-Wall®

Nu Wall® is an extruded aluminium system designed & extruded in New Zealand. Over a dozen profile variants give specifiers a wide choice, from traditional weatherboard style to ultra-modern options.

Its ease of installation negates the need for any specialised contractors to install and the great advantage is that from a construction perspective no other trades (e.g. painters) are required to follow. Therefore at the completion of the Nu-Wall® installation, expensive access can immediately be de hired as the elevation is complete.

Cladding Systems is proud to be the Australian distributors of the Nu-Wall® range of architectural cladding products, suitable for high-end residential and commercial use.

Close all

Energy Efficient

Recycled aluminium uses only 1% of the energy required to produce aluminium from scratch. This makes Nu Wall® a very environmentally friendly cladding selection for your next project. To further reduce waste Nu Wall® is extruded specifically to your project requirements – on larger projects a combination of lengths can be ordered at no cost penalty.

In addition, on projects of a reasonable size, you have the option of choosing energy-efficient Cool Chemistry® powder coat finishes from Interpon® that under lab conditions have created up to a 20° C drop in substrate temperatures.

Extensive Range of Finishes

With Nu Wall® you have the ability to choose colours from the extensive Interpon® or Dulux® powder coat colour selector, from standard Colorbond® colours to pearlescent and textured options. In addition certain Nu Wall® profiles are also able to be anodised either in matt clear or a variety of coloured anodise choices.

Anodising gives the Nu Wall® system a natural metallic look displaying the natural colour variants of aluminium, a look that some specifiers strive for in their designs. Please contact us and seek advice on which profiles are suitable for the anodising finish.

Our products can and have been used on areas as diverse as entrance foyers, shop fit-outs and garage doors. As far as specialised finishes are concerned your future specifications are limited only by your imagination – speak to Cladding Systems to explore the options.

Unlike traditional cladding products on the market when you specify the Nu Wall® system your selection and mixing of finishes is limited only by your imagination. No other system gives you the versatility to combine and blend colours and finishes in the same wall and best of all no further refinishing required.

New Developments

This will no longer be an issue when you use Cladding Systems products. We offer a variety of timber finishes that can be applied to all of the Nu Wall® profile range.

Although these finishes are slightly more expensive than standard powder coat or anodise finishes the long term maintenance issues faced with the specification of natural timber far outweighs the initial additional cost.

Using similar processes to the timber look a polished stone look can be applied to the Mono 200 profile allowing you to introduce a high price look at a fraction of the cost. What’s more, you don’t need specialised tradespeople to perform the installation.

Do you want to specify standing seam zinc, yet your client’s budget precludes this feature of your design? Cladding Systems, in conjunction with the development team at Nu Wall®, have come up with an all-new alternate that will allow you to achieve this look at a fraction of zinc cost. By combining the Mono 200 profile and the new standing seam ancillary your design will no longer be compromised by budget.

Warranty

Cladding Systems is a well-established company that supplies Australia-wide. We have an excellent reputation in the building industry, and we stand behind all our products.

Profiles

Aero 70 is suitable for either horizontal or vertical installation, and each extrusion profile has a cover of 140mm (i.e. each aerofoil is 70mm wide). The repeating aerofoil profile provides a finished appearance having a continuous surface, with inter-board joints being indistinguishable. The profile is compatible with contemporary designs; either as total cladding, or in combination with another Nu-Wall profile, or other material.

Aero 115

Aero 115 is suitable for either horizontal or vertical installation. The repeating aerofoil profile provides a finished appearance having a continuous surface, with inter-board joints being indistinguishable. The profile is compatible with contemporary designs; either as total cladding, or in combination with another Nu-Wall profile, or other material. Note that although the single extrusion profile is narrower overall than the Aero 70 and Aero 200, it only contains the one, larger 115mm wide aerofoil.

Aero 200

Aero 200 replaces the Aero 190 and is suitable for either horizontal or vertical installation. Each extrusion profile has a cover of 200mm (i.e. each aerofoil is 100mm wide). The repeating aerofoil profile provides a finished appearance having a continuous surface, with inter-board joints being indistinguishable. The profile is compatible with contemporary designs; either as total cladding, or in combination with another Nu-Wall profile, or other material.

Classique

Though one of the original Nu-Wall profiles, Classique still enjoys great popularity with those wishing to design and build a more traditionally-appearing dwelling. Typically finished in a conservative, solid powdercoat colour, this profile is difficult to distinguish from painted timber weatherboard. Nu-Wall Classique is suited to installation in a horizontal orientation. Each board has 136mm coverage.

E200

Literally hot off the press the new Eden profile provides a negative detail to the original Mono 200 profile. Suitable for both horizontal and vertical applications, it provides a sleek, modern look. Each board has 200mm coverage.

Louvre 30

Louvre 30 is the most textured of the Nu Wall profiles and offers a mini bevel-backed appearance. Each extrusion offers 120mm cover width. An ideal application is as feature cladding, combined with another Nu-Wall profile, or with other cladding materials in contemporary designs. Note that this profile requires a traditional fixing through the board rather than the standard clip.

Louvre 60

Louvre 60 offers a mini bevel-backed appearance with 120mm cover width. An ideal application is as feature cladding, combined with another Nu-Wall profile, or with other cladding materials in contemporary designs.

Louvre 120

While being essentially a bevel-back weatherboard profile, Louvre120 can also be used to stunning effect in contemporary designs when finished in colours appropriate to the application. Metallic or pearlescent powdercoats, or Natural Silver anodising can achieve these kinds of results. Each board offers 120mm of cover.

Louvre 150

The Louvre 150 is a brand new extrusion and has been created in response to a demand for a wider louvre profile. It is a bevel-back weatherboard profile that can also be used to striking effect in contemporary designs when finished in colours appropriate to the application. Metallic or pearlescent powdercoats, or natural silver anodising can achieve these kinds of results. Coverage is 150mm.

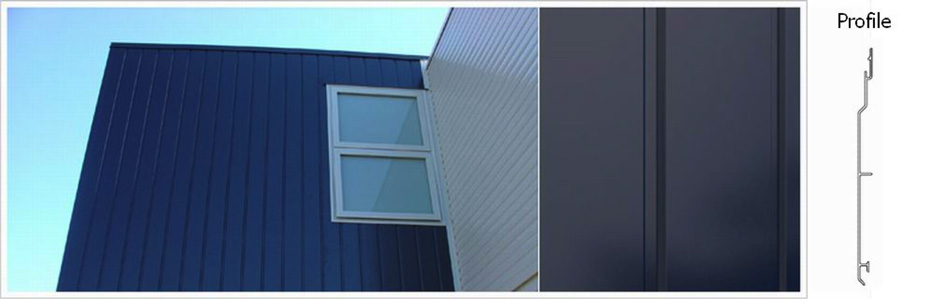

Mono 200

Nu-Wall Mono 200 replaces the Mono 190 profile offers a cost-effective alternative to composite sheet aluminium products. The finished appearance of the cladding is a flat, continuous surface, broken only by the fine inter-board joint. The 200mm wide profile can be installed in either a vertical or horizontal orientation.

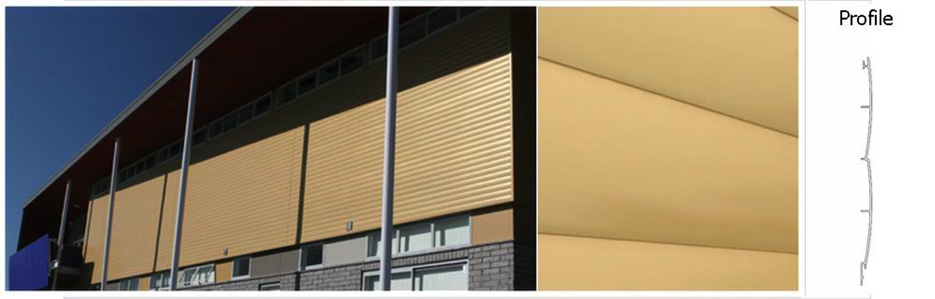

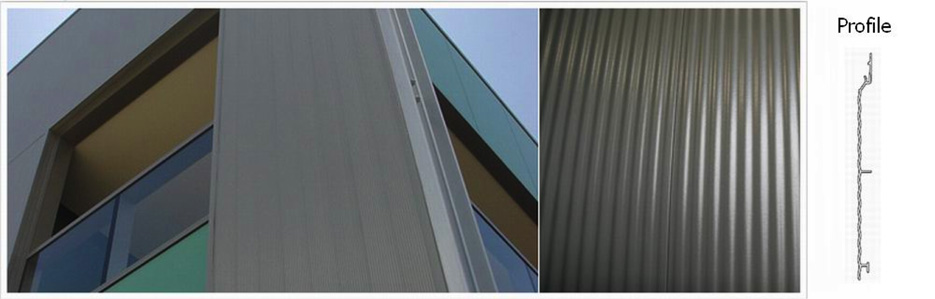

Ripple 150

While having a profile fundamentally similar to the larger-format Ripple 200, this 150mm wide version has its inter-board joint designed to provide the appearance of a continuous surface. Suitable for either horizontal or vertical installation, each board has 150mm coverage.

Ripple 200

The micro-corrugated profile of Nu-Wall Ripple200 has an expressed, visible inter-board joint; the finished appearance showing the distinctly separate cladding boards. This profile lends itself equally well to both horizontal and vertical applications. The wide 200mm cover enables speedy cladding of large areas, such as on commercial buildings. This section replaces the Ripple 190 profile and has 200mm coverage.

Shiplap

Shiplap is one of the original Nu-Wall profiles; installed horizontally it offers a straightforward, no-nonsense alternative to painted timber weatherboards. This profile also lends itself well to more contemporary applications; particularly when finished in a less conservative colour and installed in a vertical orientation. Each board has 150mm coverage.

Ullos 1

Nu-Wall Ullos was designed by Bull-O’Sullivan Architecture of Auckland as a premium exterior cladding for certain significant projects of theirs. The profile was adapted to be compatible in all respects with the Nu-Wall system. This avant-garde profile is suitable for either horizontal or vertical installation. Each board has a coverage of 162mm.

Ullos 2

Ullos 2 is a bolder version of the original Ullos, and adds striking visual texture to any building. It is suitable for commercial and domestic use and can be installed in a horizontal or vertical orientation. Each board has a coverage of 162mm. Note that this profile requires a traditional fixing through the board rather than the standard clip.

Downloads

.

Horizontal Cladding over Cavity

BRANZ Appraisal #550 (PDF)

Standard detail drawing set; HC (PDF)

Installation Reference; HC (PDF)

Vertical Cladding over Cavity

BRANZ Appraisal #870 (PDF)

Standard detail drawing set; VC (PDF)

Installation Reference; VC (PDF)

Horizontal Direct-fixed Cladding

BRANZ Appraisal #557 (PDF)

Standard detail drawing set; H (PDF)

Installation Reference; H (PDF)

Vertical Direct-fixed Cladding

BRANZ Appraisal #556 (PDF)

Standard detail drawing set; V (PDF)

Installation Reference; V (PDF)

Technical Documents

Nu-Wall Statement of Performance (PDF)

Nu-Wall Specification Reference (PDF)

Masterspec Nu-Wall branded section (MS Word)

Nu-Wall Profiles

Nu-Wall Profiles (PDF)

Nu-Wall Profiles (DWG)

Nu-Wall Profiles (DXF)

Other Documents

Nu-Wall NZ Brochure (PDF)

Nu-Wall Australia Brochure (PDF)

Nu-Wall General Information (PDF)

FAQ Sheet (PDF)

Environmental Information (PDF)

Horizontal cladding; set-out to joinery head (PDF)

Jamb Liner dimensions for joinery manufacturers (PDF)

MetecnoKasset

A durable, insulated wall & ceiling panel with a modified PIR (Polyisocyanurate) fire-retardant core & high performing thermal properties.

MetecnoKasset is available in a range of COLORBOND® colours, a palette of choice to create an inspiring interior and exterior finish.

.

- A complete system

- Tested & Passed all criteria for AS 5113 – External wall and Fire Spread requirements

- Manufactured in Australia

- New level of fire protection

- New level of thermal properties

- Prefab sections delivered directly to site

- Slot into place and secure

- Build, clad and insulate all in one

- Modular unit for seamless window/ wall junctions

- Durable & versatile Architectural System

- Extensive colours and finishes

Low & High-Rise (wind rated up to 250m)

- Testing & engineering in Australia by Ian Bennie & Associates & Inhabit Group

- Registered Design & Regulation 1507: Certificate of Compliance

- Full test rig accreditation to Australian standards AS/NZS 4284:2008 (Structural SLS, Air Infiltration, Water Penetration, Structural ULS.)

Fast & Economical Alternative to Tilt Panel

- Lightweight & easy to install (up to 50% faster)

- No need for perimeter scaffolding. Installed over handrails or behind screens.

- 2 floors p.w. cycle at Yorkshire Brewery Apartments

Close all

Module Specifications

| Module Thickness | 115 mm |

| Module Height | Made to measure up to 3800mm in height |

| Module Width | Made to measure incorporating 1100mm wide panels |

| Mass | 22.1 kg/m2 |

| Acoustic Properties | Rw 25-37* |

| Thermal Performance | ‘R’ Value: 4.91 W/m2K; ‘U’ Value: 0.20 m2K/W |

| Module composition | Modified FM approved PIR (Fire –retardant Polyisocyanurate) panel with prefinished profiled steel skins and internal skin lined with 6mm fibre cement. |

| Frame Material | Anodized or Powder coated extruded Aluminium with extruded weather seals |

| Colours | Choice of any Colorbond® standard, metallic or custom colour for external skin, frame and trims. |

| Finishes | Panel surface can be supplied in Plain, Fineline, Satinline or Ribbed profiles. |

*depending on system

Tests and Engineering

| Façade Fire Evaluation testing to NATA accreditation requirements by Exova Warringtonfire Aus. | Testing to AS 5113 according to their tendency to limit the spread of fire across their surface and between neighbouring buildings and integrates international standard test methods where practicable. |

| Building performance testing in Australia to NATA accreditation requirements by Ian Bennie & Associates | Structural SLS, Air Infiltration, Water Penetration and Structural ULS test procedures and performance requirements in accordance with standard AS/NZS 4284:2008, Testing of Building Facades. Optional tests: including BMU

restraint, seismic loading and seal degradation. |

| Engineering certification to the provisions of the section B1 of the Building Code of Australia and the Australian Standards by Inhabit Australasia | AS/NZS 1170.0:2002- Structural design actions – Part 0: General Principles

AS/NZS 1170.1:2002, Structural design actions – Part 1: Permanent, imposed & other actions AS/NZS 1170.2:2002, Structural design actions – Part 2: Wind actions AS/NZS 1664.1:1997, Aluminium Structures AS4100:1998, Steel Structures |

| Codemark Certification | Coming Soon |

Projects

Contact Us

CLADDING SYSTEMS

36 Temple Dve, Thomastown, Vic, Australia | 03 9466 3660

Copyright – All Rights Reserved